CNC Milling Metal & Plastic Parts

From 1 off Prototype to Mass Production

Start With A Free Project Review

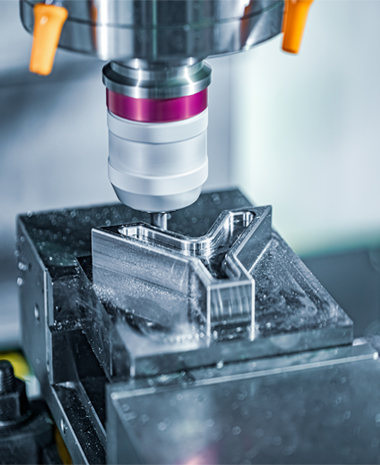

CNC MILLING SERVICES

Tarswin is one of the best CNC shops in Slovenia, offering CNC milling services for various industries. With our precision 3-, 4- and 5-axis CNC machining centers, combined with other advanced capabilities and our experienced team, we can offer high-quality custom CNC parts as well as fast delivery. We guarantee your CNC milling projects will be handled smoothly by our in-house CNC department and supplier network, which means your team can focus on bringing your product to market. So if you’re looking for a reliable CNC milling company, contact us today to get your CNC parts in days.

See why our customers love us

We received the CNC parts that you made for us, and I finally had a chance to open up the box and have a look at them today. They look very good! I am very impressed with the quality of your parts. The small details look very accurate, and the clear silver anodizing on the aluminum parts looks very clean and bright. Very nice work. Thank you!

Our advantages of CNC milling

1. Cost Efficient

80% of aspect and mechanical parts can be CNC milled within minutes or even seconds by optimizing the tool paths and using special cutting tools. With automation set up, CNC milling is super cost-efficient for mass production comparing with additive manufacturing in most of the cases.

2. Materials & Finishes Options

Besides of fast turnaround time, various type and spec of the plastic, metal block are available for milling, and different type of surface finishing is available for CNC milling parts, such as painting, anodizing and chroming. It’s great a combination of function and aspect.

3. Unlock Complexity

Because the cutting tool of a milling machine can approach the workpiece from several different angles, it is possible to create complex shapes CNC machines with more axis can create parts of greater complexity. If a CNC project demands an irregular shape, milling is often the best bet.

Typical CNC Milling Parts That We Offer

CNC milling is very flexible way to create prototype or manufacture high volume end-used parts. Plus wide ranges of milling materials are available, it fit most types of projects. Our CNC experts know how to cut your parts fast to reduce the cost, and how to mill the complex geometry with tight tolerence in different materials. We have delivered million+ high quality CNC parts to our worldwide customers.

Mold Components

CNC milling is playing an important role in mold making. Mold cavities, mold bases, sliders, lifter, and other mold components can be milled.

Plastic and Metal Valves

Parts like valves, engine house which require complex geometry and tight tolerance. We can make such part with our 5 axis CNC milling.

Medical Parts

CNC milled implants in medical-grade material. We are familiar with bone fracture plate and other components which can be used in surgery.

Automotive Prototypes

In most of the cases, the most important thing is how you can mill the part fast for cost efficient. But this is a oppositive example. it is all about how we can run the machine and the tiny cutter for over 20 hours without any issue.

Machine Components

This is a rotating cutter for a mask machines. It is important to make it sharp and in the mean time to keep the condentricity under +/-0.01mm.

CNC Milled Adapters

CNC milled aluminum adapters, tight tolerance for dimension, and angles of the holes, with alodine finish.

Overview: What is CNC Milling?

What is CNC milling?

CNC milling is a particular form of precision machining in which a cutter removes material by moving into the workpiece at an angle. The movement of the cutter is controlled by computer instructions, allowing for extreme precision and repeatability.

Milling is different to CNC turning, another popular CNC service in which a single-point cutting tool is used to cut the workpiece from block or bar materials while it is rotated at speed in a chuck. Unlike milling, CNC turning is generally used to create round or tubular shapes.

CNC milling can be used for the rapid manufacture of either prototypes or end-use parts

How CNC milling works

Like other machining processes, CNC milling begins with designers creating a digital part using CAD (Computer-aided Design) software. The file is then converted into “G-Code,” which can be recognized by a CNC mill.

CNC mills have a “worktable” and work holding device to keep a block of material — known as the “workpiece” — in place. The worktable may or may not move, depending on the style of the machine.

During the CNC milling process, the rapidly rotating cutting tool makes contact with the workpiece, cutting away material. The tool moves according to the G-Code instructions so that cuts are made in the right places until the part is finished. Some CNC mills use moving worktables to create a greater number of cutting angles.

CNC mills can cut through hard metals. This makes them more versatile than CNC routers, which are similar to 3-axis mills but less capable of penetrating hard materials.

CNC mills are different to CNC lathes or turning centers, where the workpiece rotates rather than the cutting tool.

Different types of CNC mill

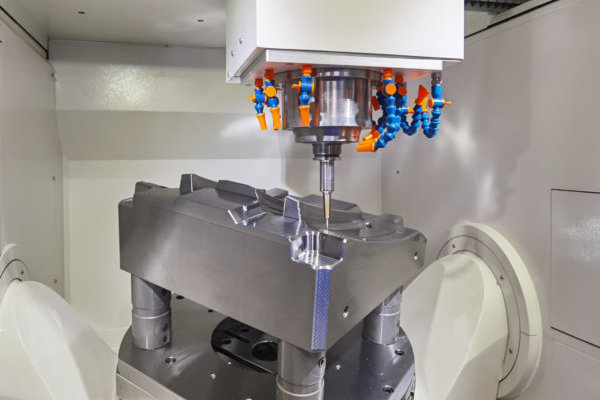

CNC mills are often defined by their number of axes. More axes mean they can move their tool and/or workpiece in a greater number of ways, giving greater cutting flexibility and the ability to make more complex parts in a shorter time.

3-axis: Standard CNC mills have 3 axes, allowing the spindle (and attached cutting tool) to travel along the X, Y and Z axes. If the cutting tool cannot reach an area of the part, the part must be removed and manually rotated.

4-axis: Some CNC mills incorporate an extra degree of movement by rotating on a vertical axis. This enables greater flexibility and the ability to create more complex parts.

5-axis: The most advanced type of widely used CNC mill is the 5-axis mill, which incorporates two extra degrees of movement, often by adding rotation to both the worktable and spindle. Parts usually don’t require multiple setups, since the mill can manipulate them into different positions.

Cutting tools for CNC mills

CNC mills can be fitted with different cutters / tools to enable different types of cutting. These include end mills, face mills, slab mills, fly cutters, ball cutters, hollow mills, roughing end mills and many others.

CNC Milling FAQ

Why use CNC milling?

Besides CNC turning, CNC milling is one of the most popular custom manufacturing processes. CNC milling is used for the majority of machined parts because it can handle a wide variety of irregular geometries. It is also an efficient means of mass production once the setup is complete

What kind of equipment do you use?

Tarswin’s facilities contain high-end 3-axis, 4-axis and 5-axis machining centers, including models from Haas and JingDiao.

Can I combine milling with other processes?

Yes. We can use a CNC machine to mill details, features and text onto parts made using other processes like casting and 3D printing.